Semi

Order

Order

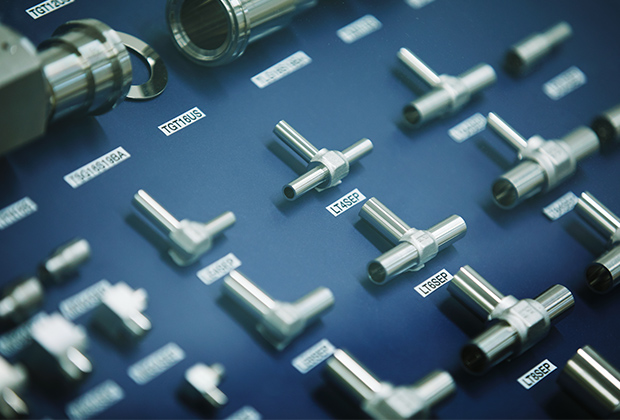

FA component division

Growing ever faster as we aim to be the fastest

in the industry.

in the industry.

Our FA component division uses an integrated production approach

in our in-house factory to increase production speed and lower costs.

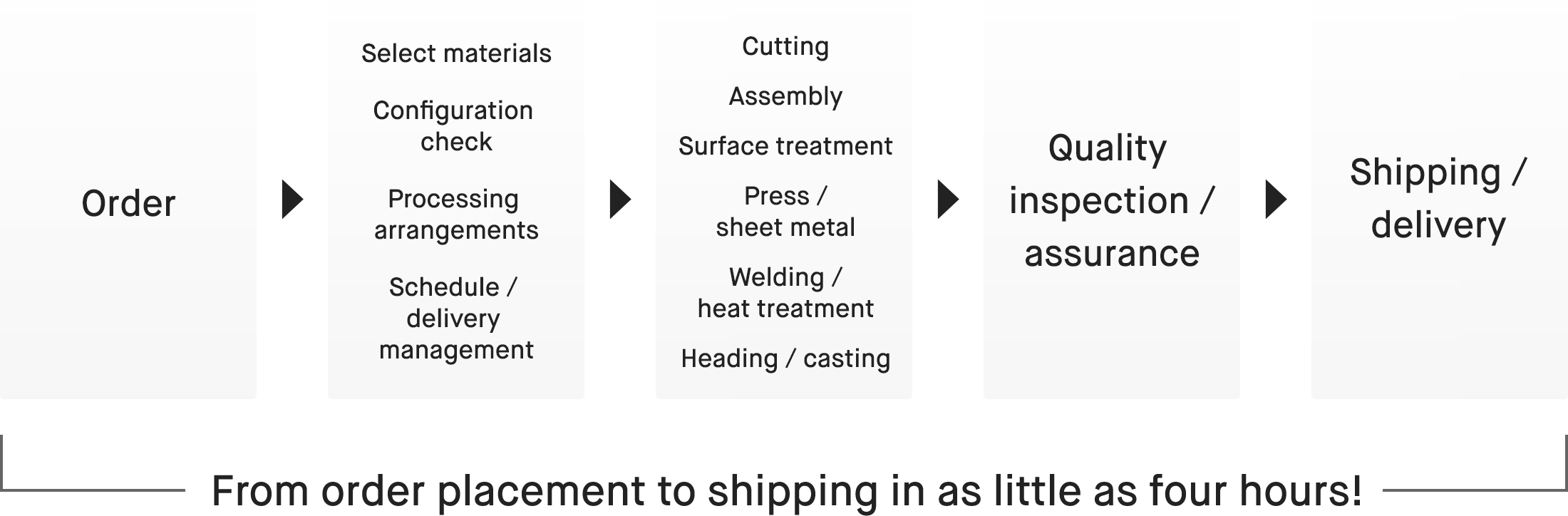

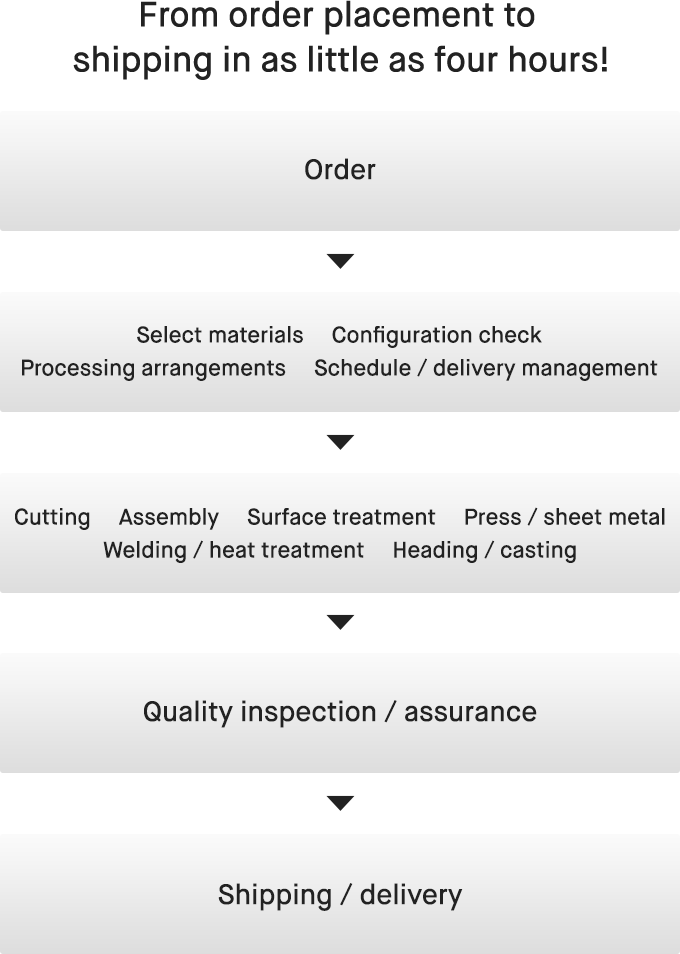

How can be provide products to customers even more quickly?

That's what's on our minds every day.Our factory operates 24 hours a day,

we make improvements to our working environment,

and we use ideas from the field to implement further improvements.

As a result, we are able to ship products in as few as

four hours after order placement.We will continue to make improvements

to reduce this lead time even further.

SATAKE

Quality 01

The same lead times, even for products involving numerous processes

We offer the same lead times, even for production that involves cutting, press lathe working, heat treatment, surface treatment, and other processes.We offer over 30,000 types of products, including products of different sizes.

SATAKE

Quality 02

Ultra-small lot production.

Same-day shipment of orders as small as a single screw

We offer ultra-small lot production, with same-day shipment of orders as small as a single screw.

Of course, we also offer same-day shipment for large orders as well.

SATAKE

Quality 03

We make improvements 24 hours a day, 365 days a year to provide you with ultra-short lead times

We are constantly making improvements to speed up production and provide you with ultra-short lead times.Our factory operates 24 hours a day, we make introduce state-of-the-art equipment, and we use ideas from the field to implement further improvements.The numerous small improvements we make enable us to provide shorter turnaround times.

Examples of our diverse processing technologies

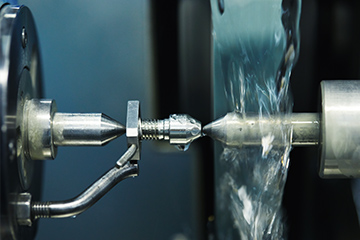

1Lathes machines

we have 40 NC Lathes machines in Yamagata facility.NC Lathes-attached with a multi-axis machining device can create any product shape with excellent precision.

2Heat treatment

Our in-house factory has salt baths with short heat treatment times, enabling us to manufacture small lots with short lead times.

3Polishing

Our cylindrical polishing equipment can achieve external tolerances on the micron level. It produces a surface roughness of 0.8a or less.

4Machining centers

Our machining centers cover both vertical and horizontal machining and can perform machining for two- and three-dimensional workpieces in short amounts of time.

5Welding

We have multiple TIG welders to perform welding for a large variety of articles with short lead times.

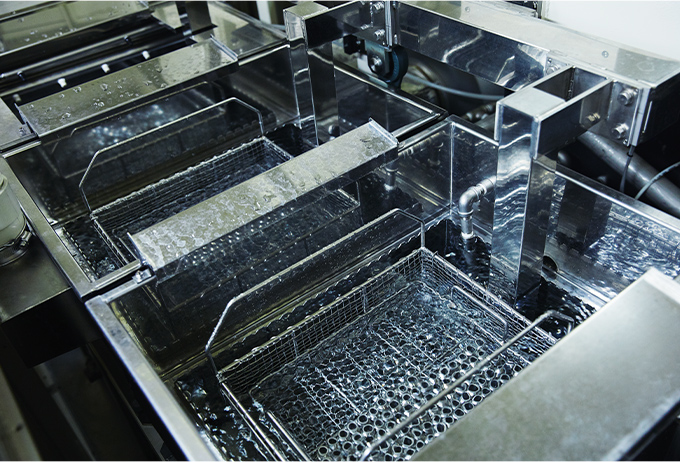

6Surface treatment

We have dedicated tanks for surface treatment, including electroless nickel, trivalent chromate, and zinc plating.

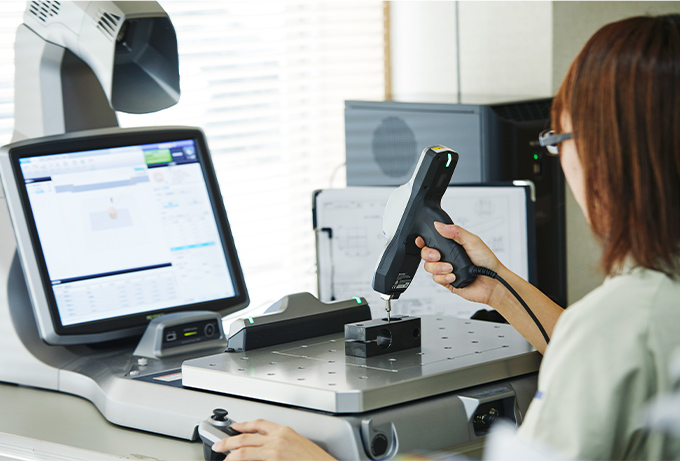

73D measurement equipment

We manage quality using state-of-the-art 3D measurement devices with AI functions.

8Database

We use a database to perform one piece manufacturing of any of roughly 30,000 semi-custom products.

9Composition analysis

We perform analysis to check that the properties of metal materials are good fits for specifications, and that the amounts of substances to which environmental restrictions apply are under restriction limits.